Installation

Write one or two paragraphs describing your product, services or a specific feature.

To be successful your content needs to be useful to your readers.

Installation Detailed

Recess covers are best fitted after most of the surrounding paving is laid, but, in the case of block or brick paving, before final compaction. The paving should be temporarily stopped around 250mm from the manhole or inspection chamber (IC) to allow room to work and enable the paving to be 'pieced-in' accurately once the cover is fitted.

Leaving the existing cover in place, to prevent spoil falling into the drain, dig out all the way around the IC about 250mm wide, and approximately 100mm deeper than the bedding layer level.

A typical IC within a paved area

Concrete is placed around IC and

rough tamped to level

Fill the excavation with a reasonably strong concrete, eg a 1:2:4 as outlined on the Mortar and Concrete page, and tamp down so that the finished level of the concrete is (depth of tray) less 25mm below the finished paving level. The tray will be placed onto the still fresh concrete and adjusted to level before the concrete sets. Alternatively, the concrete can be levelled to (depth of tray) plus 25mm, and the tray can then be fixed on a mortar bed once the concrete has set.

Once the concrete is in place, the existing IC cover can be removed and the plastic chamber section cut down to a level approx 30-50mm below the base of the new frame. This is best done with a small angle grinder, working from inside the plastic IC. Wear gloves and safety goggles, as the hot cut plastic is quite dangerous. It is important to make sure that the chamber section is cut to a level lower than the base of the frame, otherwise the tray will not sit in the frame correctly.

Cover removed and plastic

chamber cut down to suit

Frame is positioned and

concrete inside is smoothed.

The recess tray frame can now be placed over the IC, onto the concrete bed and then tapped down so that the top of the frame is level with the finished paving level. The concrete that is visible inside the frame should be smoothed with a trowel, so that it seals the inside of the frame and slopes slightly into the chamber. This is known as 'benching'. On the outside, more concrete should be placed and smoothed over the flange of the frame, to hold everything in place.

Once the concrete has started to set, the tray can be placed within the fame and the paving 'pieced-in' to suit. The pattern of the paving should be maintained as far as possible; a taut string line or straight-edge timber can be used to check that the 'lines' of the paving pattern are maintained.

The blocks or bricks within the frame can be bedded on sand or a weak mortar, and then, when the concrete has set resonably hard, say 24 hours later, the jointing sand can be applied and the whole area compacted with a vibrating plate compactor.

Tray is fitted to frame and

the paving is 'pieced-in' to suit.

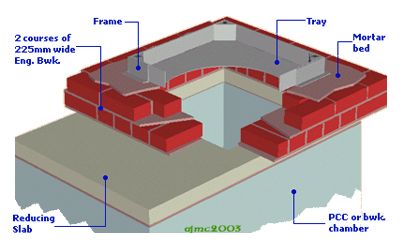

Cross-section of cover construction

Fitting a new cover to other manholes

When fixing a recess cover to a brick-built manhole or IC, the existing brickwork may be serviceable or it may have to be amended or corbelled to accept the new cover. When placing a smaller recess tray cover over a large manhole, a reducing cover may be needed. In all instances of sub-surface brickwork, only Engineering bricks should be used; commons, facing bricks, etc. are not suitable.

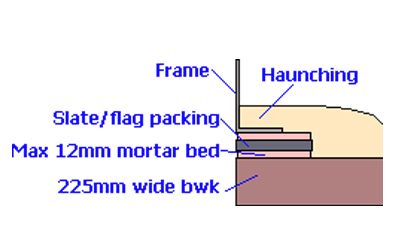

Existing brickwork should be removed to the nearest course beneath the level of the base of the frame, and the frame then bedded on a mortar bed not thicker than 12mm. If a frame requires more than a 12mm mortar bed to acheive the correct finished level, it should be raised on split bricks, pieces of concrete flags/slabs, or, for smaller adjustments, roofing slates/tiles.

Use of 'packs' to set level

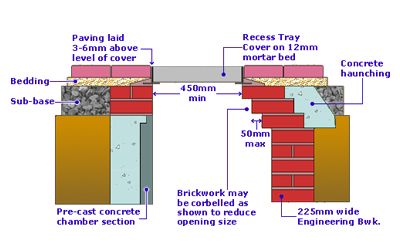

Cross-section through idealised brick or sectional concrete manhole, illustrating corbelled brickwork.

Reducing cover used on existing pre-cast concrete ring sections

With pre-cast concrete ICs, the sectional rings are removed to the nearest joint below the level of the base of the tray, and a brickwork platform constructed to carry the cover, laid on a mortar bed. In all cases where brickwork is used to carry the new cover, such brickwork must be a minimum 225mm wide, as shown, and should be laid on and haunched with concrete. Once this essential preparatory work is complete, the fitting method is essentially the same as that depicted for fitting to a circular, plastic IC, with the frame being set into a mortar bed and then haunched with concrete/mortar over the flange.

In some cases, pre-cast concrete reducing cover slabs can be used to reduce the manhole opening size. The reducing cover should be mortar bedded onto the existing manhole ring or brickwork, and 2-4 courses of 225mm wide Engineering brickwork used to establish finished level.

In the example shown here, a 1200x750mm chamber has been reduced by means of a cover slab so that a standard 600x600mm tray and frame can be fitted.